Park, Jungjin

As a material scientist, I have broad research experience and interest in the fields of magnetic materials, cellular structured materials, bio-nanotechnology, and microfluidics. I received my B.Eng. in Metallurgical Engineering & Materials Science in 1998 from Hongik University, in Seoul, South Korea. I then went on to receive his Ph.D. in Materials Science and Engineering in 2006 at the University of Maryland, College Park. The title of the thesis was “Development of bioMEMS device and package for a spatially programmable biomolecule assembly”. During the graduate program, I contributed to developing a robust bioMEMS device and packaging technology realized as the fabrication and operation of microfluidic bioMEMS devices to exploit programmable biofunctionalization for metabolic engineering. I pushed ahead with new ideas, from improvements to new concepts, resulting in one of the most powerful bio-microfluidic platforms available. (Lab on a Chip 6 (10), 1315-1321, 2006). After graduating, I was offered a position as a guest researcher at the National Institute of Standards and Technology (NIST). My experience at NIST involved the development of physical standards and methods for nanoscale measurements. The main objective was to establish new methods of elucidating and controlling nanoparticle adsorption/desorption on the surface of biological/synthetic templates. Particular effort has been devoted to the physical characterization (optical properties, hydrodynamic radius, and concentration) of luminescent nanocrystals (quantum dots) for biomolecular detection and imaging. (Soft Matter 6 (21), 5581-5588, 2010)

As I qualified as a scientist by my achievements and abilities in the areas of materials science and nano-biotechnology, I kept pursuing my career as a research scientist. I joined Prof. Alison Flatau's group as a postdoctoral fellow in the aerospace engineering department at the University of Maryland in 2009. As a team member of a nanostructured materials research group with Prof. Alison Flatau’s advising at UMD, I was responsible for developing a prototype biomimetic MEMS pressure sensor utilizing magnetostrictive Fe-Ga nanowire array as artificial cilia. In this research, I investigated various aspects of the nanostructured material properties by intensively using electron microscopes and scanning probe microscopies. I demonstrated magnetization rotation of Fe-Ga nanowires and measured hysteresis and magnetostriction of individual nanowires using magnetic force microscopy. (Journal of Applied Physics 107 (9), 09A954, 2010)

Most recently, I broadened my research area further to absorb more innovative trends in the field of aerospace engineering. I started working with Prof. Norman Wereley on amorphous glass cellular structure and magnetorheological elastomer composite. Cellular structures are used in a wide variety of commercial and military applications as buoyancy foams, energy absorbers, heat exchangers, acoustic and thermal insulation, and lightweight structural components. I am investigating the sintering kinetics of glass foam and energy-absorbing properties with a material science background. (Materials and Manufacturing Processes 34 (9), 1026-1034, 2019) Also, my research firstly is focused on 3-D printing MRE samples, followed by measurement of mechanical properties of the printed MRE with varying magnetic fields to see the magnetorheological effect.

As a material scientist, I have broad research experience and interest in the fields of cellular structured materials, nanotechnology, magnetic materials, and additive manufacturing.

Recently my three major research areas are:

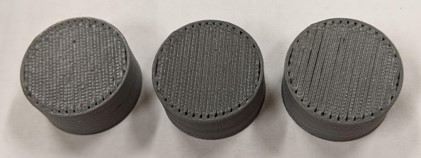

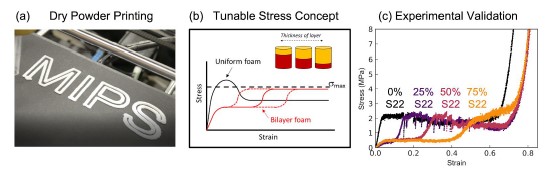

1. Amorphous glass foams using hollow glass microspheres: Cellular structures are used in a wide variety of commercial and military applications as buoyancy foams, energy absorbers, heat exchangers, acoustic and thermal insulation, and lightweight structural components. I investigate sintering kinetics and energy absorbing properties of glass foam. (Process parameter effects on cellular structured materials using hollow glass Spheres, J Park, et al, Materials and Manufacturing Processes 34 (9), 1026-1034, 2019) I developed a dry power printing (DPP) system which is a new manufacturing technique to fabricate amorphous glass foam using microspheres, enabling systematic productions of glass foams. I am interested in tunable stress–strain curves thru co-cured bilayer formed using the DPP system to limit impact stress and achieve a higher energy absorption capacity. The interesting tunability feature of the co-cured bilayer foam would be achieved by programming the thickness of each layers so that the range of each plateau stress can be adjusted, allowing the control of energy absorption.

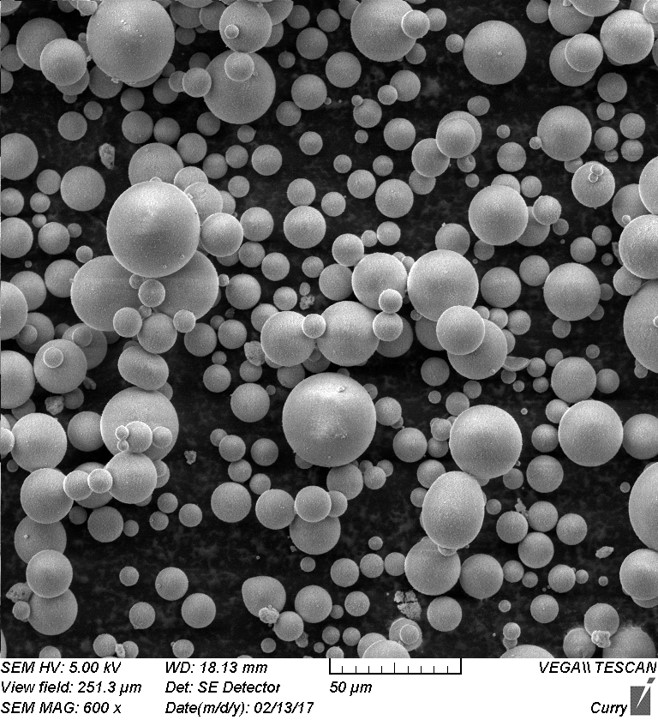

2. Development of E-glass sphere former system: Formation of hollow spheres relies on hollow jet instability phenomenon, although it should be noted that introduction of a coflowing finite density viscous fluid into the jet is a stabilizing influence. The primary parameters to be investigated are temperature and crucible pressure. My research will be focused on studying these parameters in conjunction with real time monitoring of sphere formation and after the relationship has been established, they will be coupled. Optical (Scanning Electron Microscopy), mechanical testing (Micro Compression Testing Machine) on individual sphere will be performed.

3. Flexible magnetorheological elastomer (MRE): Magnetorheological elastomers (MREs) serve important uses for vibration damping and smart material applications. My research is focused on 3-D printing MRE samples, followed by measurement of mechanical properties of the printed MRE with varying magnetic field to see magnetorheological effect. The system is composed of carbonyl iron particles in thermoplastic polyurethane (TPU) matrix.